Product Standards for Apple 4 Battery Holders

I. Introduction

In the world of consumer electronics, the importance of product standards cannot be overstated. These standards ensure safety, reliability, and performance, which are critical for user satisfaction and brand reputation. One such product that exemplifies these standards is the Apple 4 battery holder. This blog post will delve into the various product standards that govern the design, materials, and performance of Apple 4 battery holders, highlighting their significance in the broader context of electronics manufacturing.

II. Understanding Battery Holders

A. Definition and Function of Battery Holders

Battery holders are essential components in electronic devices, serving as the interface between the battery and the device itself. They securely hold batteries in place, ensuring proper electrical contact while allowing for easy replacement. In the case of Apple products, battery holders are designed to accommodate specific battery types and sizes, ensuring optimal performance and safety.

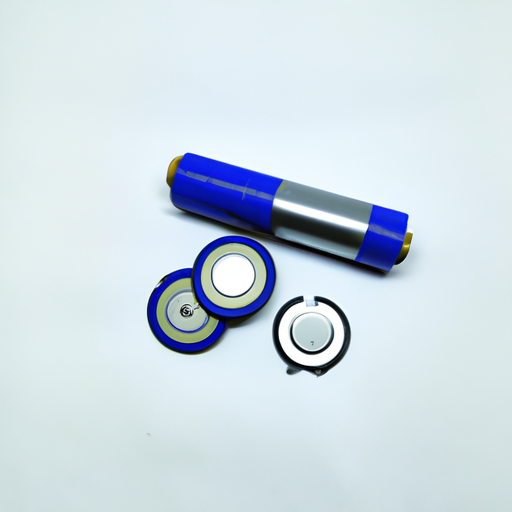

B. Types of Battery Holders Used in Apple Products

Apple employs various battery holder designs across its product range, including smartphones, tablets, and laptops. Each design is tailored to the specific requirements of the device, taking into account factors such as size, weight, and power consumption.

C. Specifics of the Apple 4 Battery Holder

The Apple 4 battery holder is designed to accommodate the unique battery specifications of the iPhone 4. It features a compact design that maximizes space within the device while ensuring secure battery placement. The holder is engineered to facilitate efficient power transfer, contributing to the overall performance of the iPhone 4.

III. Regulatory Standards and Compliance

A. Overview of Regulatory Bodies

Several regulatory bodies oversee the safety and performance standards for electronic components, including battery holders. Key organizations include:

1. **International Electrotechnical Commission (IEC)**: This global organization develops international standards for electrical and electronic technologies, ensuring safety and efficiency.

2. **Underwriters Laboratories (UL)**: UL is a safety certification organization that tests and certifies products for safety and performance, providing assurance to consumers and manufacturers alike.

3. **Federal Communications Commission (FCC)**: The FCC regulates communication devices in the U.S., ensuring that electronic products do not interfere with communication networks.

B. Importance of Compliance with Safety Standards

Compliance with these regulatory standards is crucial for manufacturers. It not only ensures the safety of the product but also protects the brand's reputation and reduces liability risks. For consumers, compliance means that the products they use meet established safety and performance benchmarks.

C. Key Regulations Affecting Battery Holders

Battery holders must comply with various regulations, including those related to electrical safety, electromagnetic compatibility, and environmental impact. These regulations help ensure that battery holders are safe for consumer use and do not pose risks to health or the environment.

IV. Material Standards

A. Types of Materials Used in Apple 4 Battery Holders

The materials used in the construction of Apple 4 battery holders are critical to their performance and safety. Common materials include:

1. **Plastic**: High-quality plastics are often used for their lightweight and insulating properties. They provide durability while minimizing weight, which is essential for portable devices.

2. **Metal**: In some cases, metal components may be used to enhance conductivity and structural integrity. Metals like aluminum or copper can improve electrical performance and heat dissipation.

B. Material Safety and Environmental Considerations

Apple is committed to using materials that are safe for consumers and the environment. This includes selecting materials that do not contain harmful substances and are recyclable. The company continuously seeks to improve its material sourcing and manufacturing processes to minimize environmental impact.

C. RoHS Compliance

The Restriction of Hazardous Substances (RoHS) directive restricts the use of specific hazardous materials in electrical and electronic equipment. Apple 4 battery holders comply with RoHS standards, ensuring that they do not contain harmful substances such as lead, mercury, or cadmium.

V. Design and Performance Standards

A. Design Specifications for Apple 4 Battery Holders

The design of the Apple 4 battery holder is meticulously crafted to meet specific requirements:

1. **Size and Dimensions**: The holder is designed to fit snugly within the iPhone 4, optimizing space and ensuring that the battery is securely held in place.

2. **Connector Types**: The battery holder features connectors that are compatible with the iPhone 4 battery, ensuring reliable electrical contact and efficient power transfer.

B. Performance Metrics

Performance metrics are critical for evaluating the effectiveness of battery holders. Key metrics include:

1. **Voltage and Current Ratings**: The battery holder must support the voltage and current requirements of the iPhone 4 battery to ensure optimal performance.

2. **Durability and Lifespan**: The holder should be designed to withstand repeated use and environmental factors, ensuring a long lifespan.

C. Testing Methods for Performance Validation

To validate performance, battery holders undergo rigorous testing. This includes electrical testing to ensure proper conductivity, mechanical testing to assess durability, and environmental testing to evaluate performance under various conditions.

VI. Quality Assurance and Testing

A. Overview of Quality Assurance Processes

Quality assurance is a critical aspect of the manufacturing process for battery holders. It involves systematic monitoring and evaluation of the production process to ensure that products meet established standards.

B. Types of Tests Conducted on Battery Holders

Battery holders undergo several types of tests, including:

1. **Electrical Testing**: This ensures that the holder provides reliable electrical connections and meets voltage and current specifications.

2. **Mechanical Testing**: This assesses the structural integrity of the holder, ensuring it can withstand physical stress and repeated use.

3. **Environmental Testing**: This evaluates how the holder performs under various environmental conditions, such as temperature fluctuations and humidity.

C. Importance of Quality Assurance in Consumer Electronics

Quality assurance is vital in consumer electronics, as it directly impacts user safety and satisfaction. By adhering to strict quality standards, manufacturers can minimize defects and ensure that their products perform as intended.

VII. Environmental and Safety Standards

A. Environmental Impact of Battery Holders

The production and disposal of battery holders can have significant environmental impacts. Manufacturers are increasingly focused on reducing waste and using sustainable materials to minimize their ecological footprint.

B. Safety Standards for Consumer Electronics

Safety standards are essential for protecting consumers from potential hazards associated with electronic devices. Key safety considerations for battery holders include:

1. **Fire Safety**: Battery holders must be designed to prevent overheating and potential fire hazards.

2. **Chemical Safety**: The materials used in battery holders should not pose health risks to consumers.

C. End-of-Life Considerations for Battery Holders

As part of their commitment to sustainability, manufacturers must consider the end-of-life disposal of battery holders. This includes designing products for recyclability and providing consumers with information on proper disposal methods.

VIII. Industry Best Practices

A. Best Practices in Manufacturing Battery Holders

Adopting best practices in manufacturing is crucial for ensuring the quality and safety of battery holders. This includes using high-quality materials, implementing rigorous testing protocols, and adhering to regulatory standards.

B. Innovations in Battery Holder Design and Materials

The industry is continually evolving, with innovations in battery holder design and materials. Advances in technology are leading to lighter, more durable, and more efficient battery holders that enhance the performance of electronic devices.

C. Future Trends in Battery Holder Standards

As technology advances, we can expect to see changes in battery holder standards. This may include stricter environmental regulations, new materials that enhance performance, and innovations that improve safety and usability.

IX. Conclusion

In conclusion, the product standards for Apple 4 battery holders are a critical aspect of their design and manufacturing process. From regulatory compliance to material selection and performance testing, these standards ensure that battery holders are safe, reliable, and effective. As the industry continues to evolve, adherence to these standards will remain essential for maintaining consumer trust and satisfaction.

X. References

A comprehensive list of sources and further reading materials can be found in industry publications and standards documents, which provide additional insights into the regulations and best practices governing battery holders and other electronic components.