What is the Production Process of Mainstream Redmi Battery Charger?

I. Introduction

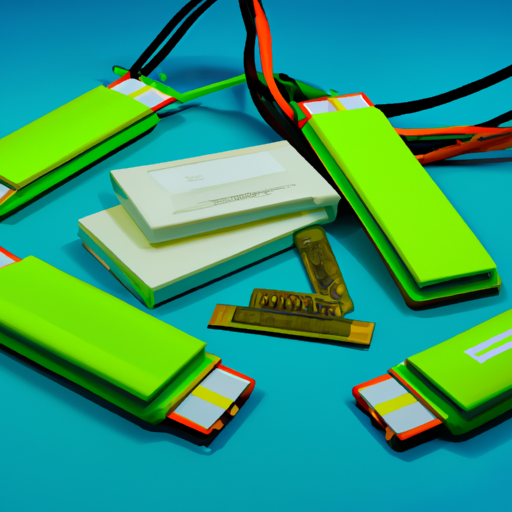

Redmi, a sub-brand of the renowned Chinese electronics company Xiaomi, has made a significant mark in the smartphone and accessories market. Known for its commitment to providing high-quality products at affordable prices, Redmi has garnered a loyal customer base worldwide. Among its various offerings, battery chargers play a crucial role in ensuring that devices remain powered and functional. In an age where technology is deeply integrated into our daily lives, understanding the production process of these essential accessories is vital. This article aims to explore the intricate production process of mainstream Redmi battery chargers, shedding light on the various stages from design to distribution.

II. Understanding Battery Chargers

A. Definition and Function of Battery Chargers

A battery charger is a device that supplies electrical energy to recharge batteries. It converts electrical energy from a power source into a form that can be stored in a battery, allowing users to power their devices without the need for constant replacement of batteries.

B. Types of Battery Chargers

Battery chargers come in various forms, each designed to meet specific user needs:

1. **Wall Chargers**: These are the most common type, designed to plug directly into a wall outlet. They are typically used for charging smartphones, tablets, and other portable devices.

2. **Portable Chargers**: Also known as power banks, these chargers are designed for on-the-go use. They store energy in a compact form, allowing users to charge their devices without needing a wall outlet.

3. **Fast Chargers**: These chargers utilize advanced technology to deliver higher power levels, significantly reducing charging time. They are particularly popular among users with high-demand devices.

C. Key Components of a Battery Charger

Understanding the components of a battery charger is essential to grasping its functionality:

1. **Power Supply**: This component converts the AC (alternating current) from the wall outlet into DC (direct current) suitable for charging batteries.

2. **Charging Circuit**: This regulates the flow of electricity to the battery, ensuring it charges efficiently and safely.

3. **Connectors and Cables**: These are the physical interfaces that connect the charger to the device being charged, ensuring a secure and reliable connection.

III. Design and Development Phase

A. Research and Development (R&D)

The production of a Redmi battery charger begins with extensive research and development. This phase involves:

1. **Market Analysis and Consumer Needs**: Understanding the target audience and their preferences is crucial. R&D teams analyze market trends, customer feedback, and competitor products to identify gaps and opportunities.

2. **Technological Advancements**: Keeping abreast of the latest technological innovations allows Redmi to incorporate cutting-edge features into their chargers, such as fast charging capabilities and smart charging technology.

B. Prototyping

Once the initial research is complete, the design team creates prototypes. This phase includes:

1. **Creating Initial Designs**: Designers sketch and model various concepts, focusing on functionality, aesthetics, and user experience.

2. **Testing Prototypes for Efficiency and Safety**: Prototypes undergo rigorous testing to ensure they meet safety standards and perform efficiently under various conditions.

C. Finalizing Design Specifications

After testing, the design specifications are finalized, which includes:

1. **Material Selection**: Choosing high-quality materials that are durable and safe is essential. This includes selecting plastics, metals, and electronic components that meet industry standards.

2. **Aesthetic Considerations**: The visual appeal of the charger is also important. Designers consider color, shape, and branding elements to create a product that resonates with consumers.

IV. Sourcing Raw Materials

A. Identifying Suppliers

The next step involves sourcing the necessary raw materials. This includes:

1. **Components Needed**: Key components such as capacitors, resistors, and circuit boards must be sourced from reliable suppliers.

2. **Quality Assurance and Certifications**: Suppliers are evaluated based on their ability to provide high-quality materials that meet safety and performance certifications.

B. Procurement Process

The procurement process involves:

1. **Cost Considerations**: Balancing quality with cost is crucial to maintaining competitive pricing for consumers.

2. **Sustainability and Ethical Sourcing**: Redmi is committed to sustainability, ensuring that materials are sourced ethically and responsibly.

V. Manufacturing Process

A. Overview of Manufacturing Facilities

Redmi's manufacturing process takes place in state-of-the-art facilities equipped with advanced technology. Key aspects include:

1. **Location and Scale of Production**: Manufacturing facilities are strategically located to optimize logistics and reduce costs.

2. **Technology Used in Manufacturing**: Automation and robotics play a significant role in enhancing efficiency and precision during production.

B. Assembly Line Process

The assembly line is where the actual production occurs:

1. **Component Assembly**: Workers and machines collaborate to assemble the various components of the charger, ensuring each part is correctly placed and connected.

2. **Quality Control Checks During Assembly**: Quality control is integrated into the assembly process, with checks at various stages to catch any defects early.

C. Testing and Quality Assurance

Once assembled, chargers undergo rigorous testing:

1. **Functional Testing**: Each charger is tested to ensure it operates correctly and meets performance specifications.

2. **Safety Testing**: Chargers are subjected to safety tests to prevent issues such as overheating and short-circuiting, ensuring they are safe for consumer use.

VI. Packaging and Distribution

A. Packaging Design

The packaging of Redmi battery chargers is designed with both functionality and marketing in mind:

1. **Branding and Marketing Considerations**: Packaging serves as a marketing tool, showcasing the product's features and benefits while aligning with Redmi's brand identity.

2. **Environmental Impact of Packaging Materials**: Redmi is committed to sustainability, using eco-friendly materials whenever possible to minimize environmental impact.

B. Distribution Channels

Once packaged, the chargers are distributed through various channels:

1. **Online Sales Platforms**: Redmi leverages e-commerce platforms to reach a global audience, making it easy for consumers to purchase their products.

2. **Retail Partnerships**: Collaborations with retail stores ensure that Redmi chargers are accessible to customers who prefer in-person shopping.

C. Logistics and Supply Chain Management

Efficient logistics and supply chain management are crucial for timely delivery:

1. **Transportation Methods**: Various transportation methods are utilized to ensure products reach their destinations quickly and safely.

2. **Inventory Management**: Effective inventory management systems help maintain optimal stock levels, preventing shortages or overstock situations.

VII. Post-Production Considerations

A. Customer Feedback and Product Improvement

After the chargers are in the market, customer feedback is invaluable:

1. **Gathering Feedback**: Redmi actively seeks customer reviews and feedback to identify areas for improvement.

2. **Product Improvement**: Insights gained from customer experiences inform future product iterations, ensuring that Redmi continues to meet consumer needs.

B. Warranty and Support Services

Redmi offers warranty and support services to enhance customer satisfaction:

1. **Warranty Policies**: Clear warranty policies provide customers with peace of mind regarding their purchases.

2. **Support Services**: A dedicated support team assists customers with any issues or inquiries related to their chargers.

C. Recycling and Disposal of Old Chargers

As part of its commitment to sustainability, Redmi encourages responsible disposal of old chargers:

1. **Recycling Programs**: Initiatives to recycle old chargers help reduce electronic waste and promote environmental responsibility.

2. **Consumer Education**: Educating consumers about proper disposal methods is essential for minimizing environmental impact.

VIII. Conclusion

The production process of mainstream Redmi battery chargers is a complex and multifaceted endeavor that involves careful planning, design, and execution. From the initial research and development phase to the final distribution and post-production considerations, each step is crucial in ensuring that the chargers meet the high standards expected by consumers. Quality is paramount in battery charger production, as it directly impacts user experience and safety. As technology continues to evolve, we can expect to see exciting trends in battery charger technology, including advancements in charging speed, efficiency, and sustainability.

IX. References

A. Citing sources for further reading

B. Acknowledgments of industry experts and studies

---

This blog post provides a comprehensive overview of the production process of mainstream Redmi battery chargers, highlighting the importance of each stage in delivering a quality product to consumers.